Dental Implant Materials

Dental implants officially first appeared several decades ago.

Since then, to ensure a high-quality result in tooth restoration, they are constantly being improved.

Currently, dental clinics offer various options for dental implants, which quite successfully perform the functions of missing teeth, while maintaining their aesthetic properties.

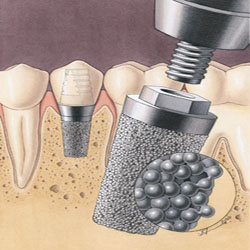

Implant a tooth is a structure consisting of two parts: intraosseous (subgingival) and supra gingival.

- Intraosseous part (implant) - is a durable and fairly compact screw, implanted in the jaw bone.

- The supragingival part is the abutment on which the denture is attached.

More recently, stainless steel, cobalt and chromium alloys were used to make implants. But today, the use of these materials is irrelevant due to the lack of resistance to various biological environments.

Implants of the first generation are also a thing of the past because of the negative impact on osseointegration, because they contain aluminum and vanadium.

Recently, dental implant materials such as titanium, zirconium, ceramics, glassy carbon and gold have been increasingly used.

Implants made from these materials fuse faster and more successfully with bone tissue, and also have several advantages in manufacturing technology.

Currently, the most popular and sought after are implants made of pure titanium and its alloys.

More promising is the use of the most resistant to chlorine compounds of titanium with niobium, which improves the structure of the material, giving it ductility and enhanced strength.

Third-generation titanium alloys containing tantalum, zirconium, molybdenum have greater biocompatibility, contributing to an adequate reaction of the jaw bone tissue to the mechanical effect of the artificial root.

Today, for implantation, the best material for manufacturing and survival technology is titanium, and zirconium is the most perfect.

- All certified dental structures are manufactured at the factory, so the quality of an implant that has a certificate of conformity should not cause concern.

- In the manufacture of implants, modern technologies are used that provide not only their reliability and strength, but also allow to achieve a high aesthetic effect.

- The surface of the structure is processed in such a way as to ensure its greatest integration into the bone tissue of the jaw.

In the manufacture of structures undergo special processing to give them a rough surface in different ways:

- Plasma spraying is performed.

- Etching of the implant surface with special acids.

- The use of machine processing.

Video: Titanium Dental Implants

Titanium benefits

Titanium is a ductile and very durable material that has a very high viscosity and is resistant to shocks.

However, in its pure form, titanium is subject to abrasion, so its various alloys are used as an advantage for the manufacture of implants.

- The surface of titanium and its alloys is quickly coated with an oxide film, which gives them anticorrosive properties.

- Vanadium free.

- Alloys are characterized by increased stability and strength and have no competitors among other materials.

- They have high biocompatibility and do not have toxic effects on the body.

- It is a hypoallergenic material, as is an absolutely inert material for the human body.

- It has no taste.

- It has good thermal conductivity.

- Quickly and painlessly fused with bone tissue.

- The titanium implant is light enough and the patient feels new teeth as his own.

Material selection

Before you opt for any material for implant implantation, you need to make sure that you have permission to use implants from this material and a certificate of conformity issued by the State Standard of Russia.

Implants, depending on what material they are made of, can be of several types:

- Bioinert. These include structures made of titanium and its alloys, zirconium, glassy carbon, gold.

- Biotolerant. These are implants made of chromocobalt alloy and stainless steel.

- Bioactive. Structures are coated with tricalcium phosphate ceramics.

Bioinert materials

Bioinert material implants have the following features:

- They are characterized by better survival.

- They have a long service life.

- Complications after implantation are minimized.

- Cases of structural rejection are minimal, as material is not perceived by the body as a foreign body.

- The presence of a high degree of compatibility of the material and bone tissue.

- The cause of implant rejection can only be a medical error. Therefore, the process of implantation must be trusted exclusively by highly qualified specialists.

Material Comparison

- Zirconium, in comparison with titanium, has a higher degree of inertness than titanium.

- Corundum ceramics are a cheaper option for implants. The likelihood of its osseointegration is significantly lower than that of implants made of titanium and its alloys.

Manufacturers

A special place in the market of implants is occupied by Astra Tech products.

Features of implants:

- The presence of a structured rough surface.

- The construction neck has micro-threads, due to which less stress and optimal load distribution are ensured.

- The structure of the implants is aimed at stimulating the formation of bone tissue and improving the process of osseointegration.

- The use of Astra Tech implants guarantees their reliable fixation in the jaw bone and has a long-term aesthetic effect.

Ankylos implants, which are made of titanium and equipped with a unique conical connection, providing maximum strength to the entire dental structure, are considered one of the best.

Life time

Modern titanium and zirconium implants are able to fulfill their function and maintain a highly aesthetic effect for many years.

Implants made of corundum ceramics will serve their master much less than titanium ones.

- The life of the implants depends both on the quality of the material from which they are made, and on how well and professionally they are installed in the jaw bone.

- The quality of the installation and manufacture of the crown also affects the life of the implant.