Veneer manufacturing

To install veneers, you will need to visit the dental clinic at least twice.

At the first visit, the doctor will prepare a tooth for installing the lining, take a cast, select the necessary color, depending on the color of the other teeth of the patient, install a temporary veneer.

In one to two weeks, the patient will need a second visit to the dentist, during which the doctor will try on the veneer and fix it on the tooth.

Materials

Veneer linings are made of different materials, the most popular are ceramics and composite materials.

The choice of material is one of the most important stages in the manufacture of veneers.

For the manufacture of structures using the direct method, modern composite materials are used.

At the same time, it is best to give preference to such materials that are the most reliable: they are not subject to abrasion, are color fast, have a wide range of color gamut, are well polished.

Technique and manufacturing technique

Methods of manufacturing veneers can be systematized as follows:

- Layered application. The veneer is made on platinum foil, which is crimped around a turned tooth on a model of plaster. The foil holds the ceramic mass deposited on it during firing in the furnace. The dental technician applies the ceramics and roasts them directly on the model itself. The technique is good in that it reduces distortion and shrinkage, as well as the cost of the technology.

- Casting method (injection molding). Wax linings are modeled on a working model, after which they are mounted on a gate and packed in a special refractory mass. Under vacuum conditions at a very high temperature, after burning wax from a ceramic or glass block under pressure, a framework is formed. After pressing (casting), the finished plates are painted in the required color. This technique simplifies the process of manufacturing veneers and is characterized by high accuracy and excellent edge fit.

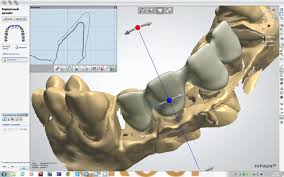

Photo: CAD / CAM Technology - Computer simulation using CAD / CAM technology. The advantage of this technology is that the workpiece can be milled, stocked and fixed in one visit to the doctor. The process of milling the lining takes no more than ten minutes. The structure is sawed off from the shank, after which it is fitted, polished and glazed. The finished structure is fixed on the tooth with a self-curing material. Veneer can be made remotely. The dentist receives an optical impression from the prepared tooth and sends a virtual model by e-mail to the milling workshop. After manufacturing the veneer, it is delivered by express mail to the clinic.

Features of veneer manufacturing by direct method

The thickness of the structure made by the direct method and made in the laboratory is significantly different.

- The thickness of the veneer made by the direct method depends on the degree of severity of the color of the tooth.

- The lighter the tooth, the thinner the veneer, and vice versa.

- Therefore, the depth of the tooth turning is determined individually by the doctor and depends on the condition of the patient’s tooth.

The advantage of a veneer lining made by the direct method is that it is made on the day of the visit to the dentist, which is very convenient for patients.

Video: “Veneers”

Manufacture and installation

Veneers go through the following stages of manufacture and installation:

- The initial appointment of the patient includes, as a rule, a medical history, clarification of complaints, examination, instrumental examination of the teeth.

- The condition of the gums and plaque is assessed.

- If necessary, x-ray, laboratory tests are carried out.

The next step is planning, which involves the study of factors such as:

- Gender, age, character of the patient.

- Smile and face shape are evaluated.

- The line shape of the gingival margin of the patient’s anterior teeth is studied.

- The individual characteristics of the tooth are evaluated, the shape, position, location of contact points, the direction of the axes of the teeth.

- The initial parameters of the restored and intact teeth are measured.

- The size of veneers is predicted and calculated.

- Demonstration of future restoration on a computer monitor.

Before starting the restoration, it is necessary to carry out professional brushing and only after that select the color of the veneers made.

Installation steps

- Cleaning the surface of the tooth from plaque. Means that do not contain oils and fluorine are used.

- Selection of the necessary shade of filling material.

- Turning the front surface of the tooth with preliminary anesthesia. The necessary amount of enamel is removed from the tooth surface. Enamel grinding depth depends on the thickness of the veneer lining.

- Taking casts. To take dental impressions, use a special spoon, on which a special paste is applied, then the spoon is pressed to the teeth until the mass hardens.

- Based on the obtained dental casts, a model of gypsum is cast in the laboratory to obtain an exact copy of the patient’s teeth.

- Production of veneer according to the cast gypsum model.

- After the preparation of the teeth by the doctor, a temporary veneer is made directly in the office.

- Trying the finished veneer after its manufacture. If necessary, adjustment is made, deficiencies are eliminated, bite is checked.

- Rinsing a tooth and veneer under running water and drying with air. Then, to increase the strength of fixation of the plate to the tooth, the doctor etches the enamel with a special gel. Only after this is the veneer fixed to the tooth using special cement.

Plaque cleansing

It is a must when carrying out any type of restoration.

- Cleansing is carried out with a special paste, which gently cleanses the tooth from plaque and dental plaque.

- The dentist applies the paste to a rotating standard polishing disc or brush and performs cleaning.

- To prevent heating, the paste is taken in large quantities.

- At the same time, saliva is a kind of saliva ejector.

- After toothpaste treatment, the tooth is thoroughly washed with water.

Ignoring this procedure leads to a fairly rapid formation of plaque around the lining and the pigmented border.

Selection of shade of filling material

When the patient is in a sitting position, under natural light, the color of the filling material is selected.

When choosing a color, the tooth and the standard should be moist, which gives them naturalness.

The choice of shade should be made in natural light.

Tools and equipment for tooth preparation

High-quality turning of a tooth before covering it with veneer requires the use of modern highly functional dental equipment.

- The preparation unit should have water-air cooling, a tip washing system, a fiber optic device, a skeler, a 270 ° rotation of the control panel around the chair, an air-water gun and a three-tip control unit.

- The spittoon should be equipped with an air-vacuum group: dust and saliva ejector, built-in clean water system.

- The presence of a lighting device - a reflector, creating a uniform illuminated field with a clear boundary.

- Equipping a dental chair with a silent electromechanical elevator makes it possible to treat a patient in a four-prone position.