Veneers E-MAX

Dental ceramics E-MAX (Germany) appeared on the market about 20 years ago, which was an excellent alternative to traditional metal ceramics.

Ivoclar-Vivadent, the manufacturer of E-MAX, is constantly developing and improving dentures that are already in demand by dentists and patients.

Dentists choose e max veneers for the following reasons:

- E-MAX material is one of the best in the restoration of teeth in some cases.

- 100% trust the manufacturer.

- Ceramics, which is offered under the name e max refers to lithium silicate glass ceramics, which has increased strength.

- The modern technology of manufacturing veneers from this material by pressing implies the creation of a homogeneous structure, the characteristic features of which are the absence of pores and tension in the material.

- These characteristics are important in the manufacture of thin veneers, as the thinner the design, the less the patient’s teeth are sharpened and the restoration looks more aesthetic.

- Durability of construction.

- Excellent aesthetic indicators of the dental structure, which is especially important when restoring the front teeth. E-MAX ceramics has all kinds of shades of tooth enamel and therefore will suit a wide range of patients. There is also the possibility of not only choosing the color of the veneer, but also transparency.

- Veneers do not change color and transparency over time. Even after 10 years, they look like new.

- Simplicity and ease of maintenance. Restorations do not accumulate plaque, and tartar deposits do not occur on their surface.

- Emax veneer has high biocompatibility and therefore is not contraindicated for allergy sufferers. The material does not interact with body fluids and therefore the gums around the restoration do not undergo changes.

Indications

- The presence of dark spots on tooth enamel.

- The presence of gaps between the teeth.

- Enamel defects.

- Changing the shape of the teeth.

Tooth preparation

Installation of veneer can be carried out both with preparation and without preparation of the tooth, if possible. Tooth turning is done only from the front side. Enamel grinding volumes for veneers e max are minimal and range from 0.3 to 0.6 mm. After installing the veneer, such a tooth will look as natural and aesthetic as possible.

Technology

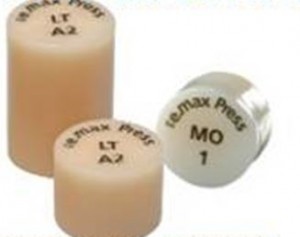

- In the arsenal of the dental technician there are ceramic blanks made of E-MAX material, intended for the manufacture of vinyl records.

- The workpiece is placed in a special furnace, where it is converted into veneer by pressing.

Manufacturing steps

- From wax, the dental technician models the veneer, giving it the ideal shape that the tooth lost as a result of decay.

- A ceramic block intended for the manufacture of veneers is sent to a special furnace.

- In the oven, the ceramic preform takes the form of a preformed wax preform.

- Almost finished construction is processed manually.

- Glaze application to simulate the natural sheen of enamel.

- If necessary, the color of the veneer is modified to match the color of the patient’s teeth.

- Fixing a vinyl record onto a patient’s tooth. Checking the bite.

- If necessary, a correction is carried out.

Care

- Daily oral hygiene at least twice a day.

- At least twice a year undergoing a professional examination at the dentist.

- Professional brushing once a year or more.